Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 45SH

Brand: Shine

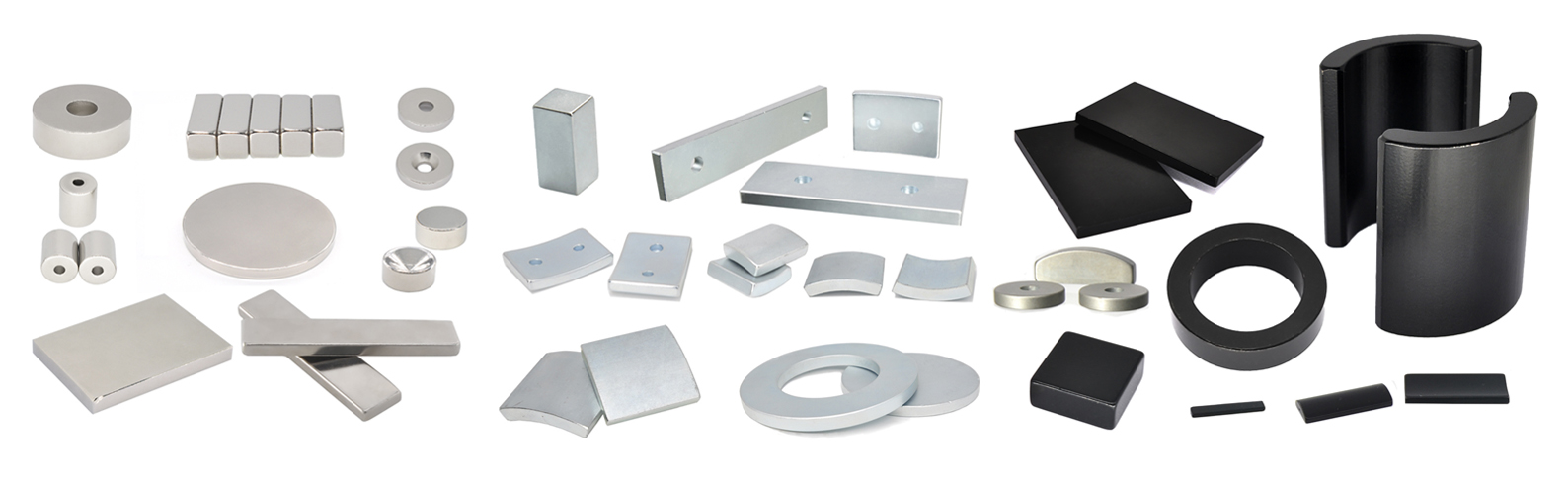

Application: Speaker,sensor.meter Etc

Shape: Ring

Grade: N50

Coating: Epoxy

Definetion: Neodymium Iron Boron Magnet

Magnet Grade: 40SH 40MGOe

Packaging: standard for sea or air

Productivity: 1000000pcs/Month

Transportation: Ocean,Air

Place of Origin: Ningbo

Certificate: ISO9001 ROHs CE

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

NdFeB magnets is the third- generation rare earth Permanent Magnet. Ndfeb is made from the neodymium, iron and boron. Ndfeb Magnet is the strongest permanent magnets compared with SmCo, AlNiCo, Ferrite magnets.

Application

Neodymium Magnet have a widely application area in modern electric and electronic products: By the using of neodymium magnet in the computers, MRI earphones, motors, alternators, sensors. Their outside dimansions will be smaller. Neodymium magnet also be called as NdFeB Magnet, they could catch iron steel, hence neodymium magnet could be designed as a magnetic catcher for catching things with ferromagnetic surface.

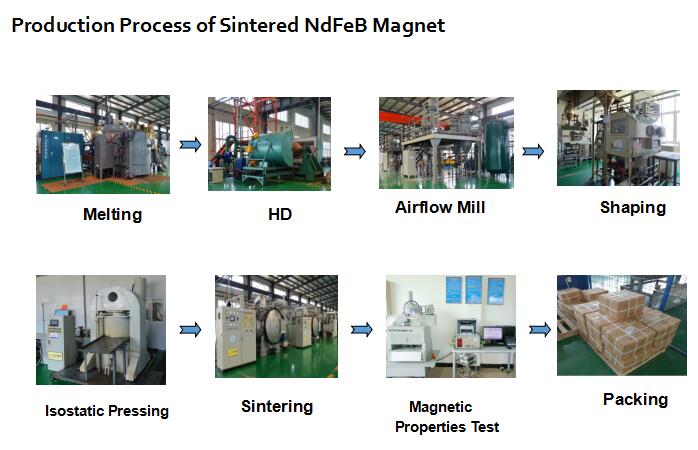

Main Manufacturing process of ndfeb magnets

1.Pressing ndfeb garins: pressing process was operated in strong magnetic environment.

2.Sintering of ndfeb blocks: sintering was processed in a vacuum furnace.

3.Wire cutting: ndfeb magnets are fragile materials operated in wire cut machines for the

tailored irregular shapes.

4.Grinding process: Grinding process: To reach the tolerance of magnets.

5.Plating: Neodymium magnets had been treated with different platings to prevent rust.

The popular platings for neodymium magnets are epoxy, nickel, NICUNI ,zinc and even

silver plating and gold plating.

6.Magnetization: the procedure are processed with magnetization machine with magnetic

feild ranged from 2~100 koe.

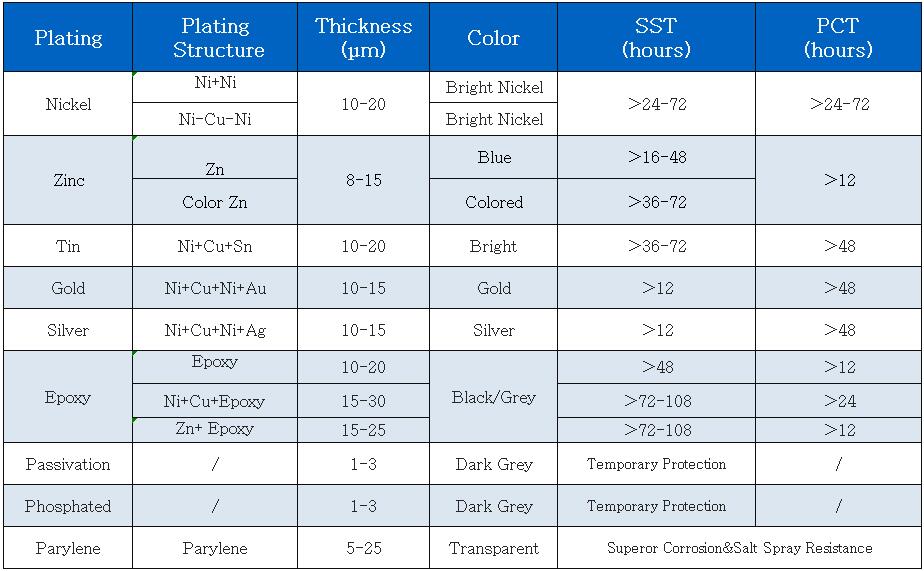

Coatings available & Tests

Coatings Available: Zinc, NiCuNi, Epoxy, Gold, Silver, Tin etc.

Tests: Plating Thickness Test,Salt Spray Test,PCT Test

Quality Guarantee

Shine Magnetics has focused on quality control since its founding. Necessary and strict checks and tests are taken in all production processes to make sure any products made by us are trouble free. To work with Shine Magnetics is to get the most reliable supplier of magnetic products. It goes without saying that our magnetic products comply with the highest quality standards. We are working continually to improve the quality and process of the products.

Following Tests Could be made as per customers` requirements:

HAST Test: Test Condition: 132.9℃, 95% humidity, 2.9 ATM, 7 days

We are factory,we can supply magnets discs at stable quality,We can supply magnets in any general size and grade.

Product Categories : Neodymium Magnet

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.