Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: N45

Brand: SHINE

Shape: Block

Coating: Nickel

Grade: N40

Definition: Ndfeb Magnet

NdfeB Magnetism: BH Max 45 MGOE

Packaging: standard for sea or air delivery

Productivity: 100,000pcs/Month

Transportation: Ocean,Land,Air

Place of Origin: Ningbo

Certificate: ISO9001,Rohs,CE

Payment Type: L/C,T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

Countersink hole Neodymium Magnet is used as a magnetic holder.Countersunk magnets are with coutersunk holes. Usually, we use supersonic wave to make the countersunk hole on neodymium magnet, neodymium magnet are brittle material, Supersonic hole process is the most quickly means to make countersunk holes.

Countersink hole is for screwing thread nail onto a wood frame or something.Thus it will be very convenient to use neodymium

magnet.

Common application: door closures and tool hangers. Popular Grade: N35 N38 N40 N42 N45 N48 N50 N52...

Neodymium magnets have 10X stronger magnetic force than Ferrite Magnet,this countersink hole magnet could hold very heavy objects.Neodymium magnet are very easy get corrosion,This countersunk hole neodymium magnet have a three layer of ( Nickel- Copper-Nickel ) coatings,which offers an excellent anti-corrosion finish for the neodymium magnet.

We could produce customize countersink hole neodymium magnet, please inform detail demensions , material grades and quantity we will quote very soon.

Use caution when handling neodymium magnets as their force may cause them to attract to metal or each other and it can be painful on the fingers if pinched together. big magnets will even broke bones, Swallow magnet is deadly and never do this.

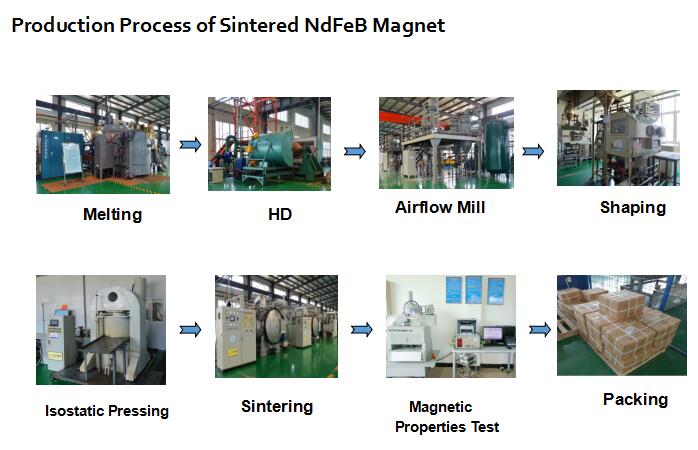

Main Manufacturing Process

Melting: In the melting furnance,the neodymium,iron,boron materals form as compund ingots.

Hydrogen demolish: Shatter the ndfeb ingots into ndfeb powders.

Airflow mill:The ndfeb powders will be milled into micron sizes.

Shaping: Ndfeb powders in the mold will be pressed as ndfeb ingot.

Isostatic Pressing: Bearing the isostatic pressure is a important process to enhance the magnetism and of ndfeb material.

Sintering:The sintering procedure, were processed in a sintering furnace under 800~1300 ℃ vacuum environments.

Cutting: After the slice cutting process,the sizes of magnets will become suitable rectangles.

Grind and polish:Neodymium magnets had been ground before they were magnetized.We could produce magnets with standard tolerances for magnets from the range +/-0.07, +/-0.05, +/-0.03, +/-0.02,and 0.01

Supersonic processing: Neodymium magnets are brittle materials and inclined to crack with impact. The supersonic technique had been applied in making counterbored holes on small size magnet.

Plating: Neodymium magnets had been treated with electrical plating,otherwise it will rust in the air. Platings that have been successfully applied to neodymium magnets are epoxy plating,nickel plating,NICUNI plating,zinc palting.

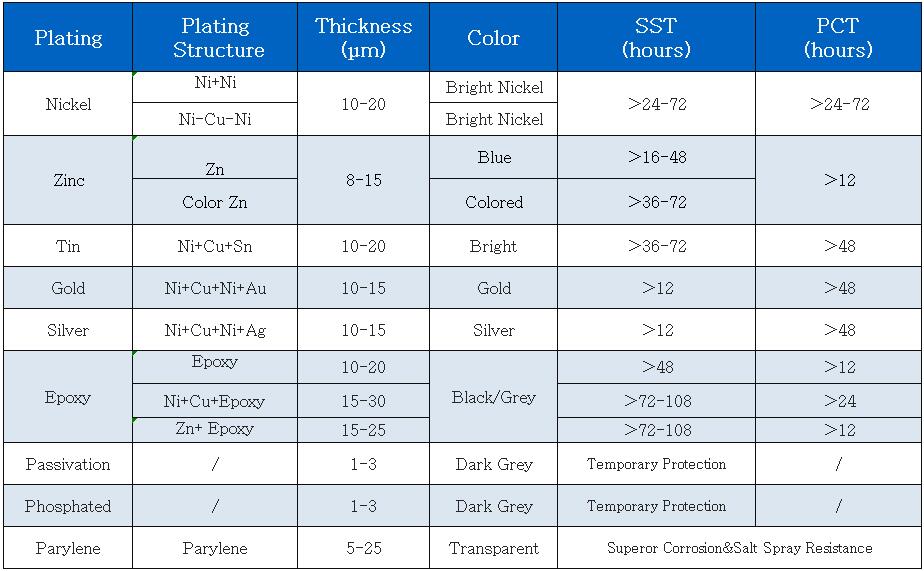

Coatings available & Tests

Coatings Available: Zinc, NiCuNi, Epoxy, Gold, Silver, Tin etc.

Tests: Plating Thickness Test,Salt Spray Test,PCT Test

Quality Guarantee

Shine Magnetics has focused on quality control since its founding. Necessary and strict checks and tests are taken in all production processes to make sure any products made by us are trouble free. To work with Shine Magnetics is to get the most reliable supplier of magnetic products. It goes without saying that our magnetic products comply with the highest quality standards. We are working continually to improve the quality and process of the products.

Following Tests Could be made as per customers` requirements:

HAST Test: Test Condition: 132.9℃, 95% humidity, 2.9 ATM, 7 days

Advantages

1 All NdFeB magnets used are made by our own magnet factory.

2 Standard producing process and strict quality checking

3 Competitive price, stable quality, in time response

4 Trained working staff

Delivery & Packing:

Popular Model: 5-10 days after receipt of payment

Customer Tailored Size: 15-20days

Packing: Plywood Box.

Product Categories : Countersunk Magnet

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.